Copper, brass and bronze may look similar, but there are things that can help you tell them apart.

Comparison is vital because these metals are easily confused.

Although there is a slight difference in colour, these can also be identified by the difference in colour.

At the same time, there are also big differences in uses and characteristics. It is important to get the right metal in the right place.

Although this article also talks about metals, in reality copper is just a pure metal. Brass and bronze are alloys. More on this in this article.

The picture below shows an example of the colours: copper, brass and bronze.

Comparison:

Copper

Copper is a non-ferrous metal that occurs almost pure in nature. Unlike bronze and brass, this metal is naturally occurring and you can use it directly in machining. It is a pure elemental metal with no other elements mixed in.

Copper is a reddish-brown metal with a shiny appearance. Copper has very few magnetic properties. Copper is one of the metals mainly used in electrical wiring due to its high ability to conduct electricity efficiently.

Copper metal has poor strength; therefore it is not often used for structural applications. Although it is not very strong, it cannot be easily broken, which means it is tough. Copper is also very flexible and malleable, so it can easily be drawn into wire-like structures. That’s why it is used in electrical wiring and in the jewellery industry. It is also a good heat conductor.

Copper is used in the manufacture of alloys. Many artists prefer to use copper in their creations because it easily oxidises to a green colour when exposed to the atmosphere.

Copper shows high corrosion resistance. It is therefore used in the manufacture and fabrication of pipes and pipe fittings. Copper also has high weldability. That’s why it’s easy to handle. There are copper articles according to the number of impurities present. However, metal containing impurities is not considered an alloy because alloys are made by deliberately mixing two or more elements.

Brass

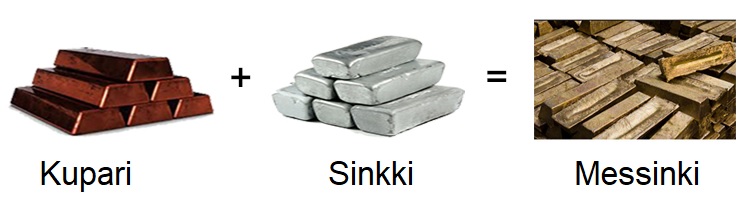

Brass can be defined as an alloy made of copper and zinc. Most copper-zinc alloys contain at least 60% copper and 40% zinc.

Brass is usually a bright golden colour, which may vary depending on the amount of zinc in the brass. Brass is corrosion resistant. It is used in places where moisture tolerance is required, such as parts of boats. It is also widely used in the construction industry as sheet, decorative items and pipe fittings. Brass is easy to work and shape, and offers a good balance between strength, durability and appearance.

Brasses are divided into three main categories: unleaded, leaded and special brass. In special brasses, other substances, such as aluminium, are added to the copper-zinc alloy to improve the brass’s resistance to rust and strength.

Bronze

Bronze is an alloy of copper and tin. Most copper-tin alloys contain at least 88% copper and 12% tin. The strength, wear resistance and corrosion resistance of bronzes are superior to pure copper. Bronze is harder than copper.

Striking bronze against a hard surface will not create sparks. This makes the mixture useful in places where explosive or flammable materials are present. Bronze is relatively brittle, but not as much as cast iron.

In air, bronze oxidises and forms a frosted copper patina. However, the patina only affects the surface and protects the metal underneath. Initially, the patina consists of copper oxide, which eventually turns into copper carbonate.

Compared to copper or brass , bronze generally has good resistance to salt water corrosion.